Cutting Tool Manufacturer Grinds Its Way to 40% Growth

M.S. Tools & Manufacturing (MSTM) has become a well-known name in the market. The Indian company produces over 600 tools a day and they credit that productivity to the automation and versatility of ANCA tool and cutter grinding machines.

MSTM provides complete customized tooling solutions for manufacturing projects.

Established in 2007 by Mr. Shoeb Rangwala, MSTM provides complete customized tooling solutions such as drill points, high-precision end mills, taper cutters, cutting tools with complex profiles and a wide range of other cutting tools. The company caters to some of the most demanding industries including automotive, aerospace, die and mold, medical, energy, mining, and 3C industries.

How it All Began

Shoeb has worked as a trader in the cutting tools industry since 1991. After gaining more than a decade of experience, he ventured into manufacturing.

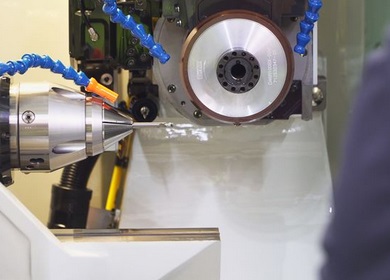

MSTM offers state of the art setup with CNC tool grinding machines from ANCA Australia. 5-axis CNC tool and cutter grinders allow the manufacturing of tools with complicated geometries and forms.

"My 10-year-long journey as a trader in cutting tools helped me understand evolving customer requirements. The exponential growth of the manufacturing industry in India, influenced me to focus my attention on the potential demand for cutting tools. To take my endeavor to the next level, I set up a manufacturing plant with a small team and basic infrastructure in 2007," said Shoeb.

Now a family business, Shoeb's son Mufaddal handles their in-house coating division and son Hatim handles the cutting tools division.

The Challenges

After establishing its footprint in the Indian market, in 2014-15, MSTM began looking for solutions that could increase the company's productivity, enhance accuracy, and reduce cycle time. Shoeb also aspired to gain a foothold in the international market and diversify into new sectors.

From end mills to taper cutters to many other cutting tools, the ANCA machines have increased productivity and versatility.

"Our operators faced difficulties while working with our older setup, as we were making multiple corrections during the manufacturing process. This issue would get amplified whenever we undertook mass production of tools. This led to extra time consumption, which impacted our overall efficiency," said Shoeb.

The Solution

MSTM was evaluating various technological options that could provide them with operational flexibility and enhanced productivity. After thoughtful consideration, Shoeb realized that ANCA machines would be the perfect choice.

MSTM strives towards complete customer satisfaction with a zero-defect target in mind.

"We purchased our first CNC grinding machine from ANCA in 2015. Considering the performance, service and prompt support, we upgraded our complete CNC machine setup to ANCA machines," said Shoeb, adding, "We found them to be more robust than our previous setup, and our issues were effectively resolved after we decided to upgrade our existing production capability with ANCA machines."

The Results

Since 2015, the company has grown by more than 40%, added many new customers, and even ventured into new sectors. In its growth journey, the company also expanded its infrastructure and currently owns six ANCA grinding machines, multiple tool inspection machines from ZOLLER and a DMG Mori VMC machine as part of their Research and Development cell.

The FX Linear machine range is ideal for everything from light manufacturing, to regrinding and full production.

Talking about the benefits of the new machines, Hatim said, "We currently have six ANCA machines. Apart from automating our operations, these machines offer the versatility of more options to meet the need for increased productivity. With our FX5, which has robotic loading capability, we have been successfully manufacturing tools without human intervention. This has, in turn, decreased our operating costs and helped us price our products better.”

Loaded with an AR300 automatic tool loader, designed and manufactured by ANCA, the FX5 Linear provides flexibility, more spindle power, and a high level of automation, thus enhancing efficiency and productivity. The FX5 Linear also has a fast tool loading and unloading cycle time of 15 seconds and enables unattended operations.

Elaborating on its impressive features, Hatim explained, "The ANCA software has enabled us to have a better understanding of the process and more options in the production and design of the tool. Their best-in-class linear drives give me control over my quality."

VIDEO: FX5E Linear

Compared to its previous production setup, the company is now able to produce 600+ tools per day. The quantum of production changes depending on the tool diameter, length, and quantity. For example, if the company manufactures standard tools in high volumes, the number of tools per hour increases substantially as compared to manufacturing special tools with tight tolerances, where production per hour drops significantly.

"We believe in investing in technology and have been continuously upgrading our infrastructure to deliver high-end solutions. It has been seven years since we have been associated with ANCA and our experience working with them has been extremely smooth and hassle-free," said Shoeb.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy